THIS WEEK

|

||

|

Robin burning the replacement steel patches to size for repairing the worn areas of the bunker with..

John bevelling the edges off the plates with an angle grinder to prepare them for welding.

Robin starting to burn out the worn section of bunker.

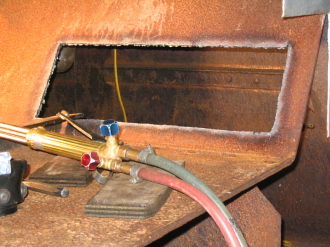

More burning out of the plate. The area to be cut out is marked in chalk then centre popped every half inch or so. The worn part can be seen running diagonally below where the torch is.

Burning complete.

Ian welding up the engine cab roof. Since the roof was in much better condition than the tender's, we have been cutting out the rotten sections and welding in new metal, rather than going for wholesale replacement, as we did with the tender cab roof.

Ian grinding the cab roof. The workmans' tent makes a good windbreak and an interesting photo.

|

The edges of the hole are bevelled to prepare them for for welding. The angle iron has been tacked on to hold he plate in position.

Repair plate ready for welding, viewed from underneath.

Mark welding the plates in place.

The finished article. This is almost the last welding to be done inside the tank, just a couple of small cracks in the floor to grind out and weld and we'll be ready to fit the new tank front. TANK PAINTING

Robin painting the inside of the tender tank. Each compartment has to be wiremopped then swept and hoovered clean before paint can be applied. We have two electric fans supplying forced ventilation during these operations. John wire-mopped another of the compartments this week to help this activity along.

The back left hand side compartment after wire-mopping and the first coat of tank paint. This is like painting araldite - slow hard work. Still, only another 14 compartments to go and the paint will help to extend the life of the tank.

|

|

| Back |

© The Carmyllie Pilot Company Ltd 2005 |

|