This week 18th December 2005

Last week Iain and I finally got the shed sorted out.

We had our annual Director's Dinner at the Carron Restaurant in Stonehaven on Saturday, which was excellent. See Gallery for fuller account and pictures.

A rather later start was made on Sunday as a result, but we got some work done. We have almost finished filing and emerying the first weighshaft journal to size.

To open up some more work fronts, we needle-gunned the two rear sand-boxes to give us a steady progression of smaller parts being refurbished. While we were at it, we made up new rubber gaskets so they will be ready for refitting once painted.

Pages updated this week: gallery, progress

Winter Sunset from my back garden. Not railway related, but never mind.

The tender brake cylinder received its first coat of primer today.

This week 4th December 2005

This week, we finished off the fascias and guttering for the shed roof.

We dragged out the tender brake cylinder and got it buffed up and primed, in preparation for refitting it.

We also ground off the 'spragging device' which had been tack welded to the drag box to aid the riveting process.

Earlier this week I went to visit Ballantynes Iron Works in Bo'ness, to see about getting new weighshaft bearings cast, followed up by a visit to Archibald Youngs in Kirkintilloch, to find out about non-ferrous castings (window frames, oilboxes, etc.) A good trip and nice to know that a few such firms still exist in the face of cheap imports from abroad.

We cleaned up the journals on the weighshaft for inspection and measurement, and started building up the worn areas with weld.

Pages updated this week: infrastructure, dragbox, progress

This week 27th November 2005

All the materials for recovering the shed roof arrived during the week, so we made that our priority task for today, and managed to complete the job before it got dark. Now the shed is starting to dry out and Iain is well on with organising the space.

No pictures today as I left my camera at home, so this old one of Ian will have to suffice.

The tender buffer beam, with all structural work now finished on both the tank and frames.

This week 20th November 2005

Last week, Ian, Iain and John completed the rivetting of the dragbox buffer beam, and refitted the stocks for the miniature buffers.

This week, we ground off the excess length on the bolts on the stocks, and demolished the redundant chimney on Max's outhouse so we can recover the roof to make it waterproof.

We also renewed the tarpaulin on the tent covering the tender frames. The old one had lasted two years, but was looking fragile.

Iain came down on Saturday and sorted through our stock of materials - the aim is to have quick and easy access to all the things we need regularly, not easy to achieve when you don't have too much storage space.

Pages updated this week: dragbox

This week 6th November 2005

If last week was a learning cuve, then this week was a learning plateau. Next week will probably be a learning roller coaster. Still, we got another four 3/4" rivets put in before having to modify the spragging device again.

We made a start on needle-gunning the weighshaft, and have obtained some replacement bearings that will bolt up to the dragbox to support the centre section (the old ones were completely worn out, in fact one of the sections was cracked in two).

Another video production, Ian's Hat can be downloaded by right clicking the title and saving the target. Note that it will not run properly if you attempt to open it straight off the web.

Pages updated this week: painting

We charged up the planet's batteries and made sure it would start

No. 6, No. 16 and No. 1 and the CCT in the autumn sunshine at Bridge of Dun

This week 29th October 2005

This week was a bit of a learning curve. We set out to put in the 3/4" rivets holding the lower dragbox to the front tender buffer beam.

The weather was rather wet, but we got the forge set up and the tools looked out.

The main problem was the lack of space in the drag box to hold up the rivets. We made up a tool from steel bar drilled to accept a rivet snap, which could be spragged in place to hold the hot rivet whilst the head was formed. That was the theory, anyway.

We spent all afternoon working out how to stop the 'holding up' tool from shaking loose and fabricating various wedges to achieve this.

We achieved a grand total of four rivets, but we have proved the method and the remainder should go in next week without too much bother.

Right click here to save our first video production the dragbox Note that this file is 4.4Mb and will take a long time to load if you don't have broadband

Pages updated this week: dragbox

This week 23rd October 2005

Over the last couple of weeks Ian, Iain and John have completed filling and rubbing down the remaining tender tank paintwork and applied black topcoat to the remainder of the primed surfaces, leaving just the cab interior to complete. Iain has trial fitted the brake and steam heat pipe brackets on the tender frames.

This week we made up a new threaded end for one of the brake pipes (the original was badly wasted) and welded it up. We also cut up a scrap length of rail to make a lintel for Max's shed.

Ian got a new cap, so the scabby old one was ceremoniously burnt and captured on video. Once I get the hang of the editing software I'll put it on the website.

The tender tank with first black topcoat complete

Kentmere Reservoir

This week 2nd October 2005

This week Iain and Davie rubbed down and undercoated the tender brake pipes. Ian was rubbing down the north side of the tender and applying stopper to the last remaining defects.

I'm afraid my contribution this week was limited to taking the photos on my way back from the Lake District (See left).

Last week we painted the inside of the cab with it's first coat of cream paint and started the final rubbing down of the north side. We also had a bit of a tidy up, storing away some of the parts we have now completed, until we are ready to refit them.

Pages updated this week: painting

This week 18th September 2005

Last week Ian and Iain, ably assisted by Iain's friend John Villiers, extended our main line by 50%. The extra 30 feet will allow us to reposition the wheels and pony truck when we get the crane in to lift the tender tank.

This week we completed preparation of the rear of the tender and applied the second coat of black paint. We also rubbed down some of the paintwork in the tender cab and painted the tender cab roof black.

Pages updated this week: painting, infrastructure

Our newly extended running line!

The back of the tender rubbed down and and ready for it's second coat of black gloss.

This week 4th September 2005

This week Smiffy was away on his annual pilgrimage to the Great Dorset Steam Fair.

John and Ian rubbed down the rear of the tender. The weather was misty and humid so we could not paint it, so we took the opportunity to get the grass cut and generally tidied up the site.

Robin completed the modifications to the coal step to let the doors open freely, and went round the bolted joints of the tender cab roof with flexible sealant, prior to painting the cab next week.

Lastly, we made a start on straightening out some kinks in the tender tank ladder.

Pages updated this week: progress, painting

This week 28th August 2005

During the week John came down and painted the back of the tender tank in black. The tank is starting to look quite good now but will need a lot of rubbing down before the second coat of black is applied in order to achieve a good finish.

We set up Max's pillar drill in the bothy and installed Ian's drill in the CCT to take it's place. Ian's drill is 3-phase and too big and heavy to fit in the bothy, but is ideal for heavy duty and precision work. Whilst doing this we had a bit of a tidy up.

We also refitted the damaged part of the bunker door, Ian welded up the broken hinge. The coal step will now need some minor modifications to enable the doors to open past it.

The sieve boxes have been topcoated, this is another workfront completed.

Finally we marked out and drilled the mounting holes in the footplate for the brake cover, and turned down some countersunk screws so the heads would sit flush in the base.

From this angle and distance the tank looks complete.

g

The tender footplate complete and ready for topcoating.

( Photo by John Yule)

This week 21st August 2005

Over the past two weekends Ian has completed the repairs to the water level gauge and re-assembled it inside the tank. All the painting inside the tank is now complete and the tank is ready for it's leak test.

Iain has topcoated the bunker in black bituminous paint, this completes the work on the inside of the bunker.

John has finished the priming of the tender cab and beneath the footplate (see opposite).

Davie Murray has almost completed the repointing of the shed.

This week we were visited by David Fraser and his family - unfortunately they missed seeing the next lot of black topcoat going on the bunker by about a hour. The tank is almost ready to go back on the frames now.

John was down to the Welshpool & Llanfair Light Railway for the June gala - click here for some photos

This week 8th August 2005

Over the last couple of weeks we have completed welding in the bunker floor and fabricated and tacked in place the new coal step. The tender buffer beam has been primed, as has most of the tender front.

This week Mark came down and completed all the remaining welding on the tender tank.

We topcoated the buffer beam, this completes the painting on the tender frames apart from a bit of touching up around the drag box.

With the big jobs on the tender tank all complete, we started sorting out some of the smaller more fiddly repairs. Ian made up a patch for the water gauge float and brazed it on, and made up a new arm from 1 1/4" pipe.

Iain went inside the tank and prepared the last of the bare steel for painting with tank paint. It's a bit claustrophobic with the end back on, but all set up with forced ventilation and 110V festoon lighting.

Ian and Iain show off the brazed repair to the level gauge water float.

The bottom will be soft soldered back on.

This is the reason the website is getting updated less frequently just now.

This week 17th July 2005

Once again, work offshore has kept me away from 46464. But work has continued apace, with some of the 'friends of 46464' lending a hand in recent weeks.

Mark the welder has been down and welded up the cracks in the tender floor and he and Ian have almost finished all the welding on the tender footplate. John has finished priming the inside of the bunker and has wire mopped the tender front, ready for priming. Davie has started repointing our storage shed, as part of an ongoing process to improve our storage facilities (ie, stop it falling down!)

This week we tacked the bunker floor in place and got about a third of the way through welding it in. We also tacked the bearers in place for the hand brake cover and water scoop blanking plate.

Now the tender tank is almost complete, only one person can work on it at a time, so we needle-gunned the tender buffer beam to give us something else to paint.

Pages updated this week: progress, painting

There is an experimental slideshow that can be viewed from the gallery page. It takes a while to load, as the sound file is quite large.

This week 26th June 2005

Sunday was a beautiful sunny day, and another of those rare days with plenty of visible progress.

We cut out the remainder of the openings in the tender footplate and got it welded into place.

We also offered up the bunker floor and, with a little judicious flame cutting of the corners to clear weld beads, it now fits snugly in place ready to be welded in.

By this time we were on a bit of a roll, so we cut off the corroded bottom third of the water scoop blanking plate and cut out a repair section and welded it in place.

We had several visitors today, including George Boyadjieff from California, whose father used to work on the Acheson Topeka & Santa Fe Railroad.

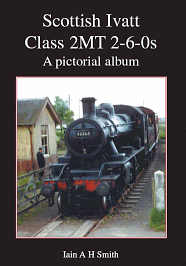

Iains' book is flying off the shelves, over 200 copies now sold. It is now also available from the Caledonian Railway's gift shop at Brechin station.

Ian welding inside the tender tank.

g

Large prairie tank 5199 looking good at Llangollen. We had a break down in Chester and took the opportunity to visit the Llangollen Railway. Click Here for more pictures.

This week 19th June 2005

Sorry for the lengthy gap between updates, offshore trips tend to play havoc with engine restoration activities.

Whilst I was away, the tank front has been welded in and the underside of the tank has been rubbed down, primed and topcoated. The inside of the bunker is in the process of being primed, so the new bunker floor can be welded in place. The sieve boxes have been given their first coat of primer.

Last week we marked out and cut the steel for the tender footplate and supporting brackets, and welded the supports in place.

This week we tack welded the remainder of the footplate components in place and fitted up the complete assembly on the tank.

Many thanks to the Angus Transport Group for your kind and generous donation towards the restoration costs of 46464. We look forward to welcoming you on site over the summer.

Pages updated this week: progress

This week 1st May 2005

Sunday was alternately foggy and pouring down with rain, nevertheless we had a productive day.

Robin completed the refurbishment of both sieve boxes, hopefully the refurbishment of all the tender components will coincide with the completion of the tank.

Iain and Ian fitted up the tank front and Ian has started welding it in place. This is quite a big step for us as we removed the front of the tank three years ago.

Iains' book is selling well, with 30 copies gone already, it is available from ourselves, from Smithy direct, and at the Bo'ness & Kinneil Railway's gift shop.

Pages updated this week: progress

Mick and Louis Walton admiring the new tank front.

The RHS sieve box ready for primer.

This week 24th April 2005

Thanks to major efforts by everyone, but especially by Iain over the past couple of weeks, the painting inside the tender is now finished.

We have discovered two fatigue cracks in the tank base, caused by flexing over the years. Ian has drilled and ground them out in preparation for welding.

Last week Davie Murray made a welcome appearance and dismantled the RHS sieve box. It has now been cleaned up ready for painting and new rubber gaskets made up for the base.

The grass cutting season is once again on us, but this means it will very soon be warm enough to resume topcoating of the tender tank.

Pages updated this week: progress and history

This week 17th April 2005

We have mostly been painting the inside of the tender tank the past few weeks. We have almost finished applying the second coat of tank paint to all 15 compartments and will soon be able to weld the front back on.

Iain has unearthed an article written by Ian Fraser in 1965 to mark the closure of the Carmyllie branch, 40 years ago in 1965. Click here

Thanks again to Gordon Petrie, for his donation of the top spring links for both engine and tender. The 12 tender pins are shown here.

Iain's book is out now, price only £6.95. Get your copy here

Click here for details

Ian and Robin's other project. Originally we were just going to build a small computer controlled calliope, but the project has started to grow arms and legs. The big pipes were surplus from a rebuilt Compton / Rushworth organ from a church in Altrincham.

This week 20th March 2005

The last of the internal tender tank sections have been wire mopped and cleaned down ready for painting. Thanks to John for this sterling effort.

The last couple of weeks we've done a lot of sorting out of storage space to organise things to suit the workfronts coming up over the summer. We've also stripped down the left hand side sieve box, which has a crack down one side which needs welding up. As it's cast iron, it will require specialist help.

We have recently received the refurbished tender springs back from Owen Springs in Rotherham.

Watch out next week for a preview of Iain's book.

Pages updated this week: gallery