This week 24th December 2006

For some unaccountable reason, none of us could get a pass out to play trains today, so last weekend was our Christmas celebration. John and Jane very kindly invited us all to their house for dinner, an excellent time was had by all, and the food was something else. Thanks Jane.

The next day we headed down to Bridge of Dun somewhat later than usual. As has become traditional, we did a couple of gentle jobs in the morning, before settling down to another Christmas dinner, cooked in the bothy. We had roast chicken, stuffing, vegetables, bread sauce, and Ian turned his new pre-heating oven to good use to produce the roast potatoes. After cheese and biscuits and coffee, we headed off home, promising to work much harder in 2007.

Pages updated this week: gallery, engineering

Ian reading about someone else's project

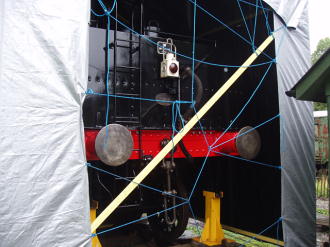

John working to remove loose scale from the boiler barrel

This week 10th December 2006

Over the past fortnight, we have finished stripping down the steelwork which supports the cab floor, and which was corroded and cracked in several places. Following our experiences with the tender, we are now just going for a total strip-down and rebuild of the engine.

Last week we had our first visit from the boiler inspector. We have only recently progressed to a point where we could start to look at the boiler, given that we are a small squad. The verdict was generally encouraging and work is now ongoing to prepare the boiler for a further inspection visit in the new year.

Ian and Glen set up the lathe to turn up the remainder of the small bushes for the spring hangers. Last week they successfully tested the pre-heating oven up to just under 300 C. Ian has also been checking the tender horncheeks, they appear to be in good condition and not requiring a lot of attention.

Pages updated this week: gallery

This week 26th November 2006

This week, we got the remainder of the cab side dismantled, and Iain got most of the constituent parts needle-gunned ready for priming and re-assembly on the new cab side.

Ian , fresh back from his trip to America, and ably abetted by Glen, cracked on with building the pre-heating oven, which started life as Sandy Ballantyne's cooker. It is almost finished now and would not look out of place in a Wallace and Gromit film!

We also rigged up festoon lighting in the boiler and had a clean out in preparation for the boiler inspector's visit next week.

Pages updated this week: history, engineering, gallery

Robin burning out rivets to dismantle the cab side

View from the cab of 46464 or 46463 at Easthaven circa 1965

Photo: Ian N Fraser collection

This week 19th November 2006

Over the past fortnight, Iain, John and myself have been removing the cab side from the fireman's side of the engine, together with the associated footplating. This was no mean feat as the assembly weighs around three hundredweight, but it is off now and work is progressing to remove the cab doors, window frames and beading, which will be re-used.

The steel for the new cab sides is on order and the rivets arrived on Thursday, so things are progressing well on this front.

This week we removed the last two spring hangers from the engine, which involved burning out the pins from both ends until they could be driven out.

Ian Fraser took many black and white and colour pictures of 46464 at work in the Arbroath area during the 1960's. Davd and Barbara Fraser have very generously allowed us access to this material, it will appear in the website from time to time.

Pages updated this week: engineering

This week 5th November 2006

After so many weeks of people being away working or on holiday, this week we had six people beavering away, consequently we got plenty done.

Last week we had to repair the big tent, which had suffered damage in the high winds. As with the other tents, the first winter shows up the weak points, but once they are eliminated, the tarpaulins last a long time, in fact UV damage from sunlight is what usually finishes them off. We also made a start on building an extractor fan for the fab shop, this involved cutting an opening in the skin and fitting a frame on which the fans were mounted.

This week we finished fabricating and mounting the weather cowling on the outside of the bothy, made some modifications to the forge, continued stripping down the engine cab, and made a start on building a pre-heating oven for when we re-metal the axleboxes.

Pages updated this week: infrastructure, gallery

Iain and Davie hunting for raw materials to make the pre-heat oven

Welding of the tender hand brake cover completed

This week 22nd October 2006

Apologies for the delay in updating the website, I've been offshore and away on holiday, plus catching up on chores at home. Other members of the team have also been on holiday during this period, but work has progressed on some fronts.

Over the past few weeks,Iain and Davie finished off fitting the water cocks and the brackets for the sieve box outlet pipes. A succession of parts have been removed from the engine cab and cleaned and primed, and a start made on needle-gunning the engine frames.

Ian and Glen have been fabricating a sturdy hop-up to use for rubbing down the tender sides, and we finished it this week. It survived mine and Ian's combined weight of 32 stone when we load tested it.

Pages updated this week: infrastructure

This week 27th August 2006

We had a lot of visitors this week, some old friends and some from much further away. Marion Preston of Carmyllie visited us to tell us about the exhibition which Carmyllie Kirk are holding next weekend, 2nd and 3rd September, entitled "Window on the Parish", the story of Carmylie Parish through pictures,words and flowers.

One of the displays will be The Carmyllie Pilot. The quarries, which the railway line used to service, will also be featured, along with Patrick Bell, one time minister at Carmyllie, and the reaper which he invented, and James Bowman Lindsay, a resident, who invented the telegraph and recognised how to make an electric lantern. (Everyone knows, of course, that the light bulb was invented by Wally Whoppernapper of South Shields. ed). Contemporary life in the village will also be covered.

The aim of the event is to raise money to restore the stained glass windows in the kirk which were originally endowed by the owners of the quarries at Carmyllie.

Marion Preston (of Carmyllie) and friend

Back of tender with fittings replaced

This week 20th August 2006

This weekend we were visited by David and Barbara Fraser, to see the work completed to date.

David brought with him many photographs of 46464, taken by his father and others during the 1960's and 70's. Some of these will appear on the 'History' page of the website in due course.

Barbara treated us to lunch at the Corner House Hotel in Montrose, which was much appreciated.

In the afternoon, we fitted the left-hand water valve and associated pipework. This was annealed and gently bent to line the joint faces up, and a new rubber gasket made for the connection to the valve.

This week 13th August 2006

We missed last week due to a combination of offshore work and holidays, but Iain was down on Saturday and got a lot of painting done, topcoating all the new bolts from the reassembly of the tender, and painting the gates across the car park.

On Sunday we welded chain along the bottom of the new tent, (tensioned with turnbuckles which Ian had picked up on his canal holiday) then secured the tarpaulin to the chain using bungy cord. This keeps the tarp taut, without pulling the eyelets out when it is windy.

We welded up the second water cock and bolted up the second water valve. The cocks will need the front of the tender tank match drilling before they can be mounted. The water pipe will need a little judicious persuasion to mate with the valve. Both these tasks will have to wait for next week.

Pages updated this week: gallery

Ian welding up the second water cock

Smiffy fitting up the water pipe brackets

This week 30th July 2006

We have spent the last couple of weekends consolidating the efforts of the work weekend.

Last weekend Glen and Ian fitted up the tender brake cylinder lubricator, having refurbished it at home. Iain had made up new brackets for the water pipes and these were match drilled and primed. The shafts where the water cocks fit onto the valves were badly corroded so we made up new ends and welded up the first one.

This week we got the rest of the brackets finished, and started cutting lengths of EN19 barstock, ready for Ian to turn up bushes for the spring hangers when he returns from holiday.

We also fixed wooden battens along the eaves of the new tent to hold the tarpaulin in place and to allow the sides to be rolled up when we are working on the tender.

No caption required!

This week 16th July 2006

Over the past 3 weeks we have been preparing for the lift. We got fine weather on the 25th June so I rubbed down the top of the tank and the dome and gave them a second coat of black topcoat. Ian started rubbing down and stopping the south side of the tank prior to final topcoating, and he and Aaron gave Max a hand to fit the water valves to the tender dragbox.

We took delivery of railway sleepers to sit the container on and the following weekend Iain and John Villiers got them set in place. (Click here for photo.) John is a Lynton and Barnstaple stalwart so the big sleepers must have come as a bit of a shock. Max, John, and Iain trial fitted the vacuum and steam heat pipework. All this work was carried out in torrential rain. (Click here for photo.)

The following weekend Iain, Max, Davie and Ian tirfored the container across the site to leave it in a convienient place for the crane to pick it up. We were fortunate to have a strategically placed tree to pull against, and to have several old superheater flues to use as rollers. They also carried out several tasks to prepare for the lift and to clear the site.

Last Thursday Iain and I were on site to prepare for the lift. We were joined by Max and Ian on Friday morning. The crane arrived at 8.30am and we got the container lifted over the engine and set in place for use as a fab shop, then moved the wheels and pony truck out onto the extra track that we laid last summer. Then we got the tank lifted onto the tender frames and lined up, and finally, made use of the crane to erect the new tent frames around the tender. Friday afternoon and the whole of Saturday were spent bolting down the tank and mounting the sieve boxes and associated pipework, miniature buffers and coupling hook. By Sunday we were getting a bit tired but got the site tidied up and the tarpaulin rigged over the new tender tent.

We still have a fair bit of work to do to put the tender back on its wheels and put up the brake gear, not to mention final painting and lining out, but we can see an end to the tender in sight, and can start turning our attention to the boiler.

During all this time John Yule has been coming down during the week and working away stripping the fittings from the engine cab and getting them cleaned up ready for painting.

Click here for pictures of the lift and this weekend's work and here for a slideshow from the recent traction engine rally at Castle Fraser.

Other page updated this week: gallery

This week 18th June 2006

No painting this week due to the rain, so we refitted the brake cylinder and associated springs and pipework. The brake cylinder is very heavy and bulky but went back on considerably quicker and easier than it came off.

We trial fitted the bearer boards to the frames and made one or two necessary adjustments, and made the rubber pads to fit the five outriggers on either side. The tank is cushioned from the frames by these 1/4" thick rubber mounts, and by the wooden bearer boards. We also dug out nuts and bolts to hold the tank down to the frames and cleaned out the bolt holes to ensure easy assembly on the day.

Finally, we stripped down the steam brake lubricator for overhaul and made a start on mounting the water supply valves in the dragbox.

The tender steam brake cylinder refitted

Glen draining the tender tank following the leak test

This week 11th June 2006

It was a baking hot and humid day today, so we decided to press on with preparations for lifting the tank, and clear the decks so we can push on with painting next week.

We put 2" of water into the tender tank to test it for leaks from the rivets in the floor. Everything was sound, so the tank is now officially finished, apart from final painting.

We levelled up the new tent frame and tack welded the brackets for the longitudinal braces, following which we dismantled the frame and completed the welding. It was so hot that we managed to get the lugs primed and topcoated by close of play.

We also dismantled the tent over the tender frames and moved it over the engine frames.

Iain fitted some new hinges to the Planet's battery compartment cover.

Pages updated this week: introduction, progress

This week 4th June 2006

With the painting of the upper part of the tender tank now complete, we dismantled the tent which has been protecting it and re-erected it over the boiler, ready for the next phase of work.

We also temporarily erected one frame of the new tent so we could square it up and weld on the mounts for the longitudinal diagonal braces. With only three people, this all took rather longer to complete than we had hoped, so we left the welding for next week and Ian, Aaron and Glen finished off the topcoating of the frames.

Opposite is shown a fine 3 ½" gauge model of 'Heilan Lassie', based on the rebuild of Gresley's P2, owned by Mr Watson of Aberdeen. It was built in 1962 by Mr Watson's father and ran during the 1970's at the Beechgrove Garden.

Pages updated this week: progress, infrastructure

'Hielan Lassie' (Photo: Christiane Taylor)

A rare view of the tender cab roof before final topcoating

This week 28th May 2006

This weekend we got one side of the tent frames and all the longitudinal members topcoated.

Work on stripping the engine dragbox and cab is ongoing.

We rubbed down and topcoated the rest of the tender cab, the tender cab roof and the bunker sides.

We also got the spring hanger bushes that Iain had recently turned pressed in.

This week 14th May 2006

Iain was up on Saturday, and finished off the priming from last week. He also did a great job of giving the bothy a coat of preservative. (Note that Aaron finished up round the back as he is the only one that can fit in there, the rest of us being somewhat dietically challenged!).

Ian finished welding up the last tent frame, and fabbed up the 2 diagonal stiffeners, following which Iain got all the parts primed.

In addition to painting the bothy, Aaron did some painting on the tender drag box where the 3/4" rivets went in and helped Iain to clean down the tender ladder ready for priming.

John has carrying on stripping the engine cab and dragbox area. Whilst the frames and main fragbox platework is in good condition, much of the cab sides and associated bracketry are badly corroded and will have to be replaced.

I got most of the tender cab painted in black topcoat.

Pages updated this week: progress

Robin painting the tender cab

Aaron painting the shed door

This week 7th May 2006

Today we welded up the final tent and the remainder of the longitudinal members, leaving just the lugs on one side of the frame to complete. This final frame has a removable bottom member so it can be installed around the tender, so took a bit longer than the other two to construct. We also got most of the parts we made today primed.

John has been down during the week and working on stripping the engine dragbox and cab.

We had an extra pair of hands today, Aaron Smith (left), who we hope to see on a regular basis.

We also cut the grass again, it's been growing like wildfire just recently.

Smithy was down at Steam in the Park this weekend, helping Mick Walton to run the miniature steam railway.

Pages updated this week: introduction

This week 30th April 2006

Another nice day, so we got on with welding up the tent frames, and got two frames finished and half of the longitudinal members fabbed up.

Iain and Glen also found time to prime all the parts finished so far.

Next week should see this project completed.

We also did some weedkilling around the site.

Ian had a call last week from Peter Todd, who worked on 46464 during its' stay at Aviemore. As well as offering some useful advice, Peter sent us some excellent photos of 46464 at Aviemore, which can be found in the History page, or acessed by the link below.

46464 at Boat of Garten 27th May 1979

Photo © Peter Todd 2006

Robin welding up the frame for the tender 'tent'

This week 23rd April 2006

Today was a beautiful spring day, so we took full advantage and Davie completed the topcoating of the tender lockers in cream paint.

We had steel delivered during the week, and started building a new improved cover for the tender when it goes back together. This is made from 2" square hollow section and will be much stronger than the existing cover. This will free up 30' of the old cover to be re-erected over the boiler, as we hope to start work on removing the firebox later this year.

Anyway, Iain and I got all the steel sections cut to size with the chopsaw and the first of three frames welded up, whilst Ian turned up another three bushes, and helped us finish off the welding.

Iain was up on Saturday and cut the grass and did some painting on the shed.

We took delivery this week of our new Fab Shop (see progress page). This will be lifted to it's final position when we lift the tank back onto the frames and, when fitted out, will double our workshop space.

Pages updated this week: gallery, progress

This week 16th April 2006

Sunday was a nice spring day, so we took the opportunity to get some rubbing down and painting done, applying the second topcoat to the inside of the tender cab upperworks. This is starting to look the part.

We also made another four small bushes for the spring hangers, only another four to go, then we can start on the large ones.

Ian brought along his latest toy, a spud gun which fires whole potatoes. It goes without saying that it would have been highly irresponsible to have attempted to let off such a weapon of mash destruction (thanks, Dean) so it stayed locked up in the car boot all day. Honest...

Pages updated this week: progress

Ian posing with newly acquired spud gun

46464 at the Strathspey Railway in the 1970's

Photo: George Morris

This week 9th April 2006

This week we continued working on the engine drag box, and repaired the tender tank ladder which had been damaged when the engine was in service. We tried to bend it straight, without too much success, so eventually we cut the damaged section out and welded in new metal, which did the trick. The alternative would have been to re-number the engine 46463, which had a shorter ladder!

Because we are almost finished restoring the tender, there are an increasing number of these 'minor' tasks, but they have to be done sometime and we need to get the tender re-assembled to free up some storage space to start on the engine.

Thanks to George Morris, who sent us a nice e-mail from Sweden, along with the photo opposite, which was particularly welcome as we have very few photos of 46464 from it's time up at Aviemore.

This week 2nd April 2006

Over the last couple of weeks Ian has been machining up bushes for the spring hangers, while Iain has drilled out the last of the replacement brackets to match the originals.

This week Davie Murray came down and finished up the pointing on the shed brickwork.

John made a start on needle-gunning the engine drag box, which is in much better condition than the tender drag box was.

I fabricated up a new cover for one of the sandboxes using a bit of old superheater flue, some 6" Sch 20 pipe and scrap 1/2" ms plate. The original cast lid was lost before we became involved with the engine.

New fabricated sandbox lid shown next to original cast version

7 1/4" gauge Ivatt class 2 under construction in Holland

Photo: Folkert Rosing

This week 12th March 2006

Another snowy day today, this time it was the Central Belt which caught the worst of the snow.

We machined up bushes and a pin for the tender brake spring link, and got the bushes pressed in. The link needs to be fitted before the brake cylinder can be refitted, so was a useful job to get out of the way. It also gave us some practice for turning up bushes, we will need to set up a production line for all the brake gear and spring hanger bushes.

Opposite is shown a very fine model of an Ivatt class 2, sent to us by Folkert Rosing in the Netherlands. We know from the web stats and from correspondence that the website gets hits from all over the world. The furthest one so far is (I think) Papua New Guinea. Please drop us a line and we'll give you a mention.

Page updated this week: gallery, progress

This week 5th March 2006

Last week we cleared all the undergrowth out from beneath our vans before it became a fire risk. By way of a bonus, it also looks a lot better.

We also rivetted up the brackets and finished buffing them up ready for priming. Photos of the rivetting, ably taken by Friend of 46464 Bill Rebecca, can be found on the progress/engineering page by clicking on the link below.

This week was one of those very rare occasions when weather stopped play for those of us who live in Aberdeen. Iain managed to get up from Fife and got all the brackets primed. Hopefully normal service will be resumed next week.

Pages updated this week: progress

Undergrowth removal from beneath our vans was long overdue.

"I'm just going outside, I may be some time".

This week 19th February 2006

Today was wet and miserable, but we got a few more jobs out of the way.

We welded up the stand we had started last week.

We also got the brackets more or less finished. I'll take some photos next week, once the rivetting and (hopefully) priming is complete.

Ian and Iain unblocked the chimney in the CCT which had been suffering from lack of use. This makes breathing and seeing easier when the stove is lit.

Page updated this week: gallery

This week 12th February 2006

This week we started preparing to refit the tender brake cylinder. We turned and cross-drilled the mounting bolts and dug out all the other components that need to be refitted at the same time. One or two parts need re-bushing, this will be carried out during the week.

There were a lot of brackets on the engine which were damaged during the move from Aviemore, these have been taking up storage space, so we decided to make a start on restoring them and get them out of the way.

We gave the steps a first coat of primer and the sand boxes their second coat.

We also cut all the lengths of angle to make a heavy duty stand, ready for welding up next week.

Pages updated this week: progress

Ian turning down the ends of the brake cylinder bolts for cross-drilling

One of the completed tender steps.

This week 5th February 2006

Over the past couple of weeks we have been rubbing down and filling the sandboxes and welding up the tender steps. Both sides are now finished and ready for priming.

We also dug out the engine steps from the store. They were in much better condition than the tender steps so did not require replacement, so we just needle-gunned and wire brushed them ready for priming.

Finally, we went through the cast components to sort out those which are damaged and will require replacement.

Pages updated this week: progress, gallery

This week 15th January 2006

Last week we finished stripping the handbrake gear and cleaned it all down. Some of the bushes are worn and will need replacing. We also got some priming done on the rear sand boxes and on the brake cylinder.

This week we finished burning off the weighshaft bearing brackets. Iain has sourced some new brackets, once we have the new bearings cast they will be match-drilled ready to be rivetted in place.

We made a start on refurbishing the tender steps, which are badly corroded. We cut off the old steps and made up two blanks for new steps, which we got folded up ready for welding up.

Finally, we are now well on with refinishing the second bearing on the weighshaft.

Pages updated this week: progress

The main casting from the handbrake after steam cleaning.

Photo: Iain Smith

Ian lapping in the bearing on the weighshaft.

This week 2nd January 2006

After an enforced weekend off, due to Christmas Day unaccountably falling on a Sunday this year, we resolved to get off the couch after the excesses of Hogmany and do some work.

The weather was bright, but cold so we could not do any painting. Ian continued working on the weighshaft, and has now hand finished the first bearing.

Iain and I set to to burn off the weighshaft bearing brackets, which have worn down too much to hold the bearings in place. We got the first one off then ran out of oxygen. The cylinders were soon loaded in the trailer for refilling during the week.

By way of a Plan B, we fetched out the handbrake gear and stripped it down for cleaning and refurbishment.

Happy New Year and best wishes for 2006 to all our supporters

Pages updated this week: progress